Precision Manufacturing + AM Technology = Value Added AM Solutions

Who We Are

Penn United Additive is a metal powder additive manufacturing service provider focused on complex, precision metal additive manufacturing part development, qualification, and production. We provide end-to-end manufacturing solutions to our customer-partners by adding value through additive manufacturing and offering the best manufacturing method for their most challenging applications.

By combining our knowledge of metal additive manufacturing with decades of experience in subtractive machining and grinding, we apply the best aspects of both AM and conventional manufacturing to help our customer-partners determine the right use and business case for AM parts. As part of our larger Penn United tooling group, Penn United Additive is able to leverage decades of precision tool and die experience to focus on providing additive manufacturing solutions to our current customer-partners throughout the markets we serve.

Since 1971, Penn United has developed strong relationships with many of our customer-partners by providing innovative, value-added manufacturing solutions. Across Penn United’s larger organization we specialize in high precision metal components, precision tooling, and hard material wear components, affording us the capability to assemble and unite all of this experience to support our AM group. By leveraging our long history of success in precision metals manufacturing with new metal additive manufacturing technology, we have been able to establish ourselves as leaders in the development of AM technology and have propelled to the forefront of the AM industry.

Our Expertise

- Engineering Services

- DfAM

- Modeling

- Drawings Design

- Topology Optimization & Lattice Design

- Heat Exchangers

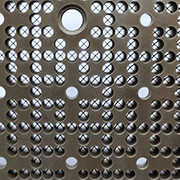

- Specialty Filters

- Light Weighting Applications

- Thin Wall Structures

- Material Development

- Feature Driven Parameter Design

- Non-Destructive Test Specimens

- Embedded Test Flaws

What We Do

Precision Secondary Operations

Developed from the industrial and manufacturing roots of the Pittsburgh region, Penn United is known in the manufacturing industry as a reliable, high precision manufacturer. With competencies in producing, maintaining, and measuring to extremely tight tolerances (less than 0.0001”), Penn United’s legacy of manufacturing capabilities allow us to approach AM part production and qualification from an industrial manufacturing perspective.

Penn United Additive is supported by:

- Over 20 precision wire and sink EDM machines

- Dozens of precision CNC machining centers

- Over 100 precision OD, ID, and surface grinders

Materials

Penn United has optimized and customized unique parameter sets for over 10 different material to be printed at various thickness layers consisting of 20um, 30um, 40um, 50um, 60um, 80um options.

Current developed materials include:

625

304L

A600

A718

17-4

Mararging 300

H13

H230

6061 RAM2

C18150

Cobalt Alloy 6

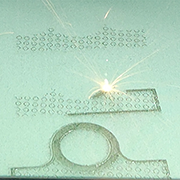

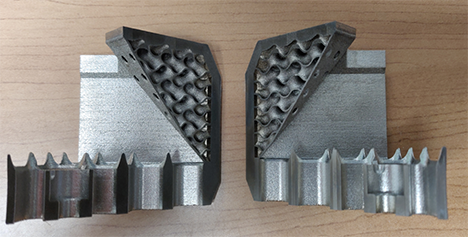

We have developed and designed builds with multiple parameter sets to run 30um/60um layers often using 30um layers for fine resolution features and 60um layers for larger features. This is useful when transitioning from 30um layers for fine mesh or fin structures in heat exchangers or fine filtering applications to thicker 60um layers for structural or frame features. This process allows us to optimize layer thickness by feature, decrease build time, and reduce cost, while maintaining fine feature control.

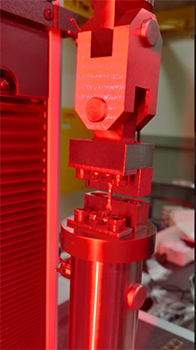

Additive Manufacturing

Utilizing the best additive manufacturing equipment and pushing it’s capabilities to new heights, Penn United is committed to utilizing the best equipment on the market to achieve our high standards.

Our Additive Manufacturing equipment includes:

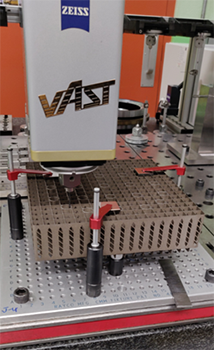

Inspection & Metrology

Driven by managing complex, precision requirements from a highly diverse set of customer-partners and markets, Penn United is heavily focused on having the best inspection equipment and metrology infrastructure available.

Our precision inspection and metrology equipment includes:

- Ziess Comet 6 blue light scanner

- Over 10 Precision CMM’s

- Over 20 OGP Smartscopes with touch, optic, and laser scanning capabilities

- Dozens of surface finish analyzers, hardness testers, and tensile test machines

- Thousands of precision fixtures and manual gauges

Design, Modeling, & Drawing Guidance

The Penn United Engineering team specializes in complex CAD modeling via Solidworks and other industry leading design tools. With decades of combined experience of CAD modeling, drawing, and quality requirements, we can help take your idea from concept to a complete qualified product with guidance on the challenging aspects of creating drawings and models for metal AM builds.

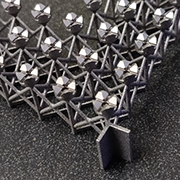

Topology Optimization and Lattice Design

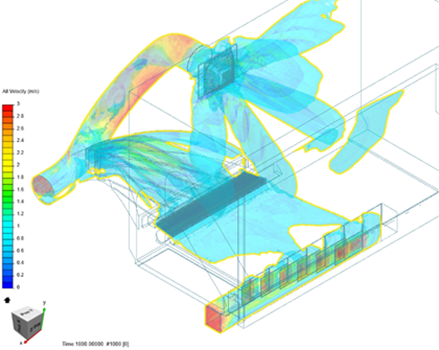

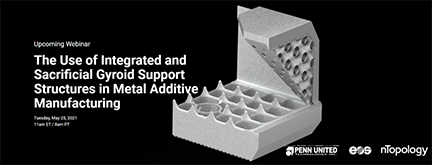

We have designed and printed hundreds of unique lattice structure designs for filtering, heat exchanger, and light weighting applications. After thoroughly researching several available industry tools we have partnered with nTopology to design complex geometries and support structures.

Penn United Additive was featured with EOS and nTopology to create a webinar on “The Use of Integrated and Sacrificial Gyroid Support Structures in Metal Additive Manufacturing.”

Non-Destructive Testing Specimens

Penn United specializes in building non-destructive testing specimens using additive manufacturing technologies. Through advanced modeling techniques and innovative improvements to machine parameter settings, embedded flaws can be printed into sample components for use in ultrasonic, radiographic, or penetrant testing.

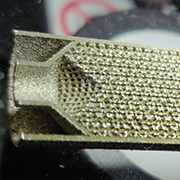

AM Machine Accessories

Through our own development of the additive manufacturing process, we have created custom accessories to improve the build process and outcome of the final printed part. We are experienced in designing and building improved AM machine accessories including custom build plates, re-coater blades, and AM fixtures. Our Engineering and Manufacturing teams can help determine the best solutions needed to solve your most challenging build problems.

Standard Build Plate Materials

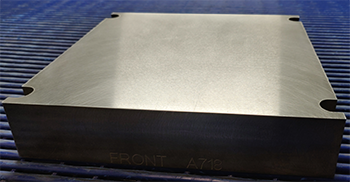

A36, 17-4, 15-5, 316L, 304L, A718, A625, C300, 6061-T6

Build Plate Improvements

Our standard build plates are made with increased thicknesses to reduce warping during builds. We also incorporated larger counterbores to allow for more efficient 12 point bolts to simplify the removal of difficult builds containing significant amounts of residual stress.

Contact us

Call Us

(724) 352-1507

Email Us

sales@pennunited.com

Our Location

799 North Pike Road

Cabot, PA 16023